Icephobic surfaces are of significant interest for the aeronautics, renewable energy, and refrigeration industries. These surfaces enhance the efficiency of such systems and ensure greater safety—one needs only to consider aircraft, which must operate reliably even under the most extreme weather conditions. Until now, the technology behind these surfaces has relied on coatings that can be fragile and prone to degradation over time.

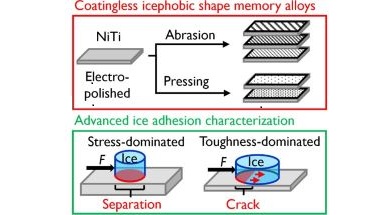

In the article “Towards Nickel-Titanium Shape Memory Alloys for Coatingless Icephobic Materials” (DOI: 10.1039/D5MH02106E), published by Materials Horizons (Royal Society of Chemistry, Impact Factor 10.7 (Clarivate Analytics, 2024)), the authors demonstrate how the mechanical properties and surface characteristics of Nickel-Titanium (a specific Shape Memory Alloy) can be engineered to achieve robust anti-icing performance, overcoming the limitations of traditional perishable coatings. The results highlight the potential of these alloys to provide a durable, coatingless solution for ice mitigation, opening new pathways for designing functional surfaces in extreme environmental conditions.

Luca Stendardo, Carlo Antonini, Davide Parlato, and Riccardo Motto of the Department of Materials Science, University of Milano-Bicocca carried out the work in collaboration with Paola Bassani and Francesca Villa from the National Research Council (CNR ICMATE) of Lecco and with Mauro Mameli from the University of Pisa.

This study was carried out within the SMARTICE project (Advanced de-icing surfaces based on engineered shape memory alloys, CUP: H53D23001840006) through the PRIN 2022 call, funded by the Italian Ministry of University and Research as part of the European Union's Next Generation EU funding.