Lithium–sulfur (Li/S) batteries are one of the most promising alternatives to conventional lithium-ion batteries, as they offer a significantly higher theoretical energy density due to the high specific capacity of sulfur, along with advantages in terms of cost and abundance of raw materials. However, practical implementation is limited by several challenges, including the low electronic conductivity of sulfur and its reaction products, significant volumetric changes during charge–discharge cycles, and, most importantly, the polysulfide shuttle effect. This phenomenon occurs when soluble lithium polysulfides form in the electrolyte and migrate between the cathode and anode, causing loss of active material and rapid performance degradation.

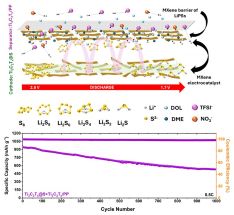

Professor Riccardo Ruffo and Professor Chiara Ferrara of the department of Materials Science, University of Milano-Bicocca, in collaboration with researchers from the University of Cordoba and Ricerca sul Sistema Energetico, have developed a new Li–S cell architecture. The two-dimensional metallic conductor MXene (a titanium carbide, Ti3C2) is used both as a support matrix for sulfur at the cathode and as a barrier layer on the polymer separator between cathode and anode. This strategy enhances the electrochemical performance of the cathode and limits the diffusion of polysulfides toward the anode.

The results, published in December 2025 in Advanced Functional Materials (Wiley, Impact Factor 19.0) in the article “Dual Role of Ti3C2Tx MXene in Li–S Batteries: Cathode Additive and Separator Modifier for Enhanced Performance” (https://doi.org/10.1002/adfm.202519742), demonstrate highly promising performance for the future commercial application of this technology.