There is nothing as simple as a water drop. And yet, understanding the drop behavior on a solid surface still represents one of the most complex scientific challenges, with a plethora of technological implications: some of them are more traditional, linked to combustion phenomena and sprays, some others popped-up more recently, such as 2D and 3D printing, as well as the development of coatings for self-cleaning and anti-icing applications.

In everyday life we are surrounded by drops: just look at the window glass, or at the car windshield, on a rainy day. Water drop adhesion is controlled by the surface properties of glass, a hydrophilic material ("it likes water").

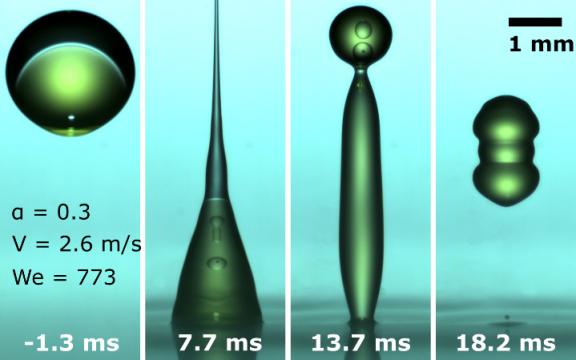

When a water drop is contaminated by an external oil layer, a different scenario opens up. As soon as the drop impacts on a glass surface, the water slides on the oil layer, which acts as a lubricant and allows water to bounce off the glass, without sticking to it. This new phenomenon was named self-lubrication. These are the results conducted by an international team of researchers, jointly led by Carlo Antonini, Rita Levi-Montalcini Fellow at the Department of Materials Science at University of Milano – Bicocca, and Marie-Jean Thoraval, professor of fluid mechanics at Xi’an Jiaotong University. The research has been published in Science Advances (Impact factor 12.8 - 2018 Journal Impact Factor, Journal Citation Reports (Clarivate Analytics, 2019)), an open access online AAAS journal, in the article "Rebound of self-lubricating compound drops" (doi: 10.1126/sciadv.aay3499).

What are the applications of this research?

This study is a perfect example of fundamental scientific investigation, which is however part of a larger project, initiated in 2016 as I was a scientist in Empa, the Swiss Institute for Materials Science and Technology. The project is dedicated to the development of new ultra-porous cellulose materials for separation of water and oil: as such, we were developing porous sponges with selective absorption of oil in water. In a recent publication (Antonini et al., Nanomaterials 2019, 9(8), 1142; 10.3390/nano9081142), we demonstrated how to fabricate nanocellulose sponges, which can selectively absorbing up to 100 liters of oil per kg of cellulose. These materials can be useful for oil remediation, to remove oil or other organic liquids that may be present in the water, and thus clean up contaminated water.

What was the benefit of an international collaboration?

Having an international collaboration was crucial. My colleague Marie-Jean Thoraval, at Xi'an Jiaotong University, has hosted the experiments in his lab, in China, to develop a system for the controlled generation of water-in-oil compound drops and to perform high-speed video recording. In the meantime, I focused on the development of the nanocellulose sponges, as I was working in Empa - added Antonini. During the project, we needed to compare the behavior of water-in-oil drops on a porous material (nanocellulose sponges) and a non-porous surface, such as glass: this brought us to discover the unexpected phenomenon of self-lubrication. Thanks to a small project funded by the Xi'an Jiaotong University in the two-year period 2017-2019, I was able to carry out research activities directly in Xi'an for about ten days a year, together with two students, Nathan Blanken and Muhammed Saeed Saleem.

How do you see the next research steps?

The research will continue with investigating more thoroughly the interaction of water and oil on porous materials. Following my return to Italy in September 2018 as Rita Levi Montalcini fellow, I am creating a new laboratory, SEFI Lab, which stands for "Surface Engineering and Fluid Interfaces". The objective is to continue to study these phenomena of interaction between liquids and surfaces. And we will certainly consolidate the so far effective collaboration with Xi’an Jiaotong University, as demonstrated by the support of a new seed project for 2019-2021.