Anion exchange membrane (AEM) technologies are emerging as a promising route for advancing the hydrogen economy by enabling the use of non-precious materials and reducing environmental impact. Unlike proton exchange membrane (PEM) systems, which rely on scarce platinum group metals (PGMs) and PFAS-based membranes, alkaline systems permit the use of sustainable, PFAS-free materials. This shift supports more resilient supply chains and lowers capital expenditures (CAPEX). Despite these benefits, the adoption of AEM electrolyzers and fuel cells remains constrained by performance gaps relative to PEM technologies.

Although significant progress has been achieved—particularly in membrane commercialization—further optimization of electrocatalysts for the hydrogen evolution reaction (HER) and oxygen reduction reaction (ORR) remains critical. Cobalt exhibits limited activity in acidic environments but performs well under alkaline conditions, especially for HER. Recent advances include incorporating cobalt into porous carbon matrices or dispersing single cobalt atoms in nanoporous graphitic carbon, resulting in reduced overpotentials. Additional improvements have been realized through nanostructured cobalt-based composites.

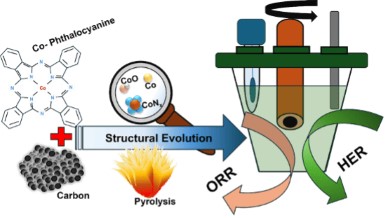

For ORR, cobalt-based, PGM-free electrocatalysts—especially single-atom catalysts—show strong potential. However, while cobalt nanoparticles enhance HER, they can hinder ORR by promoting peroxide formation. Post-treatment strategies are therefore applied to improve stability and performance. A common synthesis approach involves pyrolysis of transition metal–Nx (TM–Nx) precursors with carbon sources. This atmosphere-controlled thermal process embeds TM–Nx sites into a carbon matrix with high precision, yielding durable electrocatalysts. Parameters such as temperature, gas atmosphere, and reaction time influence particle size, porosity, and dopant distribution. Despite its widespread use, the pyrolysis process remains incompletely understood, underscoring the need for further optimization of electrocatalyst performance.

The research team of the Department of Materials Science of the University of Milano-Bicocca led by Prof. Carlo Santoro (Dr. Mohsin Muhyuddin, Dr. Jacopo Orsilli, Dr. Lorenzo Mirizzi, Mr. Roberto Landone, Ms. Sofia Faina and Prof. Massimiliano D’Arienzo), in collaboration with Prof. Plamen Atanassov, Mr. Alessio Cosenza at the University of California, Irvine, USA, Dr. Enrico Berretti, and Dr. Alessandro Lavacchi at CNR-ICCOM, Florence, Italy, Irfan Nadeem and Mitjan Kalin at the University of Ljubljana and Dr. Francesco D’Acapito at CNR-IOM (beamline BM08 ESRF) Grenoble, France, conducted a comprehensive study on the pyrolysis of cobalt(II) phthalocyanine (CoPc) mixed with Ketjenblack EC-600JD (KJB) or Vulcan XC72R over a temperature range from room temperature to 1000 °C under an argon atmosphere. The aim was to investigate the evolution of cobalt active sites and the structural changes of the carbon supports during pyrolysis.

A combination of ex situ and in situ characterization techniques was employed. X-ray absorption spectroscopy (XAS) was used to monitor changes in the chemical environment of cobalt, while a suite of microscopic and spectroscopic methods—including TEM, Raman spectroscopy, XPS, and XRD—was applied to evaluate structural and morphological transformations. This integrated approach enabled a detailed understanding of material evolution throughout the pyrolysis process. The results revealed that temperature-dependent changes in active site structures had a pronounced impact on electrocatalytic performance. In particular, hydrogen evolution reaction (HER) activity improved at higher pyrolysis temperatures due to reduced overpotentials, whereas oxygen reduction reaction (ORR) performance declined, as evidenced by lower half-wave potentials and limiting currents.

The formation of metallic cobalt and oxide nanoparticles was observed above 600 °C, with particle size increasing as the temperature rose, as confirmed by XRD, HRTEM, and XAS analyses. No oxygen attachment on cobalt sites as a fifth ligand (as observed in Fe-based electrocatalysts) was detected, supported by the consistency between in situ and ex situ XAS measurements. Enhanced HER activity was associated with the presence of cobalt nanoparticles, while ORR performance was more strongly linked to secondary active sites. Electrocatalysts supported on Vulcan exhibited superior HER performance compared to those supported on KJB, whereas KJB-supported catalysts outperformed Vulcan-supported counterparts in ORR. Overall, this integrated study provides valuable insights into the structure–property relationships of Co–Nx–C electrocatalysts, identifying key factors that govern their electrocatalytic behavior and performance.

The results of the research are reported in the paper “Electrocatalysts Formed by Pyrolysis: Temperature-Dependent Progression of Active Sites in Co-Phthalocyanine/Carbon-Derived Electrocatalysts for Hydrogen Evolution Reaction and Oxygen Reduction” (DOI: 10.1021/acscatal.5c06120) published in ACS Catalysis (Impact Factor 13.1, Journal Citation Report (Clarivate Analytics, 2024)).