Chemistry of inorganic and hybrid materials (NanoMat@Lab)

NanoMat@Lab was founded by Prof. Franca Morazzoni and aims at the synthesis and functional characterization of inorganic pure and hybrid materials for energy saving by soft-chemistry techniques.

Inorganic materials for polymer composites: filler and curing activators

The research focuses on the preparation, chemical modification and surface functionalization of i) oxide nanoparticles (mainly ZnO, SiO2 and Al2O3), ii) polysilsesquioxanes and iii) naturally occurring clays, with controlled morphological and surface features. These materials are synthesized by bottom-up approaches and employed in a wide variety of applications (i.e., automotive, tires, high performance dielectrics, smart-packaging, thermally conductive materials, self-healing). The materials are designed in collaboration with academic and industrial partners (i.e Corimav, Pirelli Tyres, Nuovo Pignone, Chimar Srl) for the production of polymer nanocomposites with enhanced structural and functional properties.

Oxide-based systems for catalysis, electrocatalysis and scintillators

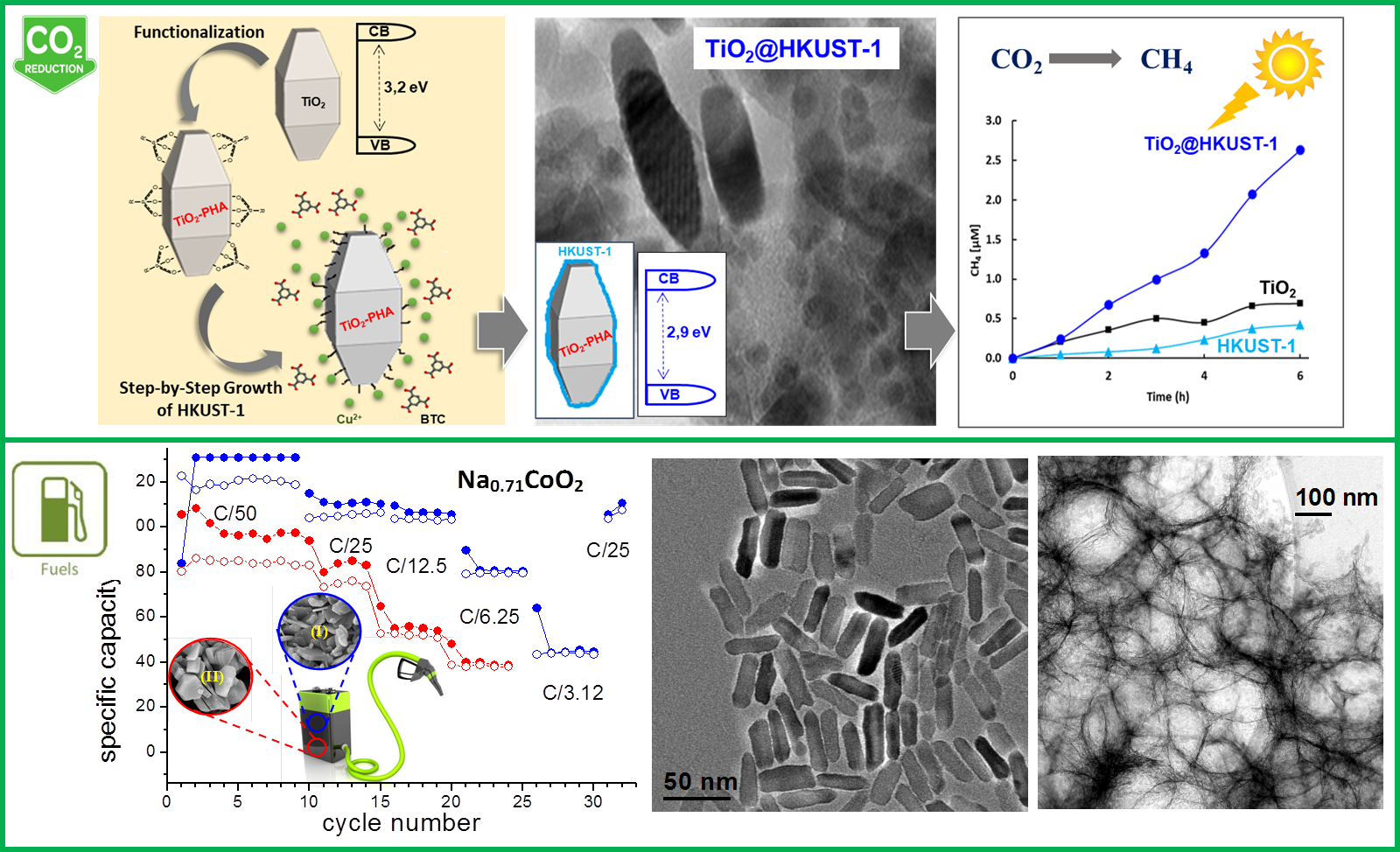

The research aims at the synthesis of morphology-controlled oxide nanoparticles (e.g., TiO2, ZnO, iron oxides, magnetic ferrites) and porous systems (macro/mesoporous silica or alumina) by soft-chemistry methods. It also investigates their (photo)catalytic mechanism through spectroscopic and spectromagnetic techniques. The possibility of tailoring size, anisotropy, and surface functionalities of these systems through soft templates and capping molecules, is herein exploited to modulate the inorganic-organic interfaces. This plays a crucial role in determining their properties and implementation to develop advanced hybrid materials for water/air depollution, CO2 conversion into valuable products as CH3OH, batteries, electrocatalysis and scintillators, also in the frame of MUSA PNRR project in collaboration with Eni.

Materials and technologies for recycling, circular economy & environmental remediation

The aim of this activity is to recover and reuse inorganic materials such as titania, silica, and iron oxides, generated as by-products from industrial processes. The main goal is the proper modification of inorganic nanoparticles derived from waste through chemical, mechanical or thermal processes, in order to impart them specific structural and morphological features. This prompts their reuse in various applications such as reinforced nanocomposites, wastewater treatments or (photo)catalysis in collaboration with industrial partners (i.e., Fluorsid, Opigeo).

Research Team

Prof. Barbara Di Credico

Prof. Massimiliano D'Arienzo

Dr. Silvia Mostoni

Prof. Roberto Nisticò

Prof. Roberto Scotti

Research Lab

U5 Building, 1st Floor, Room 1017

U5 Building, Ground Floor, Room T065

U5 Building, Ground Floor, Room T045

U9 Building, Ground Floor, Joint Lab Eni

Facilities

- two fully equipped laboratories for inorganic synthesis: solvothermal reactors, furnaces for thermal treatment up to 1500°C, Schlenk lines, mixing reactors with impeller, centrifuges;

- Flame Spray Pyrolysis (FSP)

- bench-scale plants for UV and Vis-light photocatalytic test;

- Infrared spectrometer (FTIR) equipped with the ATR crystal for solid samples;

- Thermal analysis (TGA) up to 1000 °C coupled with FTIR station for exhaust gas analysis;

- Bruker ESR spectrometer equipped with liquid N2/He Cryostat

- Physisorption and chemisorption station for surface area analysis and porosity

- Differential Scanning Calorimetry (DSC)

- Metallizer for the preparation of non-conductive samples for microscopy

The group has also easy access to:

- XRPD Diffractometer (Rigaku)

- Scanning Electron Microscopy (SEM) , and Transmission Electron Microscopy (TEM/HRTEM), in collaboration with Microscopy Platform, Universiy of Milano Bicocca;

- Solid State NMR, in collaboration with University of Trento.