Surface Engineering and Fluid Interfaces (SEFI Lab)

The Laboratory of Surface Engineering and Fluid Interfaces (SEFI Lab) focuses on research and innovation for the development of new technologies towards clean water and energy-efficient processes, two corner stones for sustainable development.

Research activities focus on understanding interfacial transport phenomena, for the design of innovative smart interfaces. SEFI Lab is characterized by an interdisciplinary approach, at the interface between thermofluidics, material science and surface micro- and nano- engineering.

Icephobic surfaces

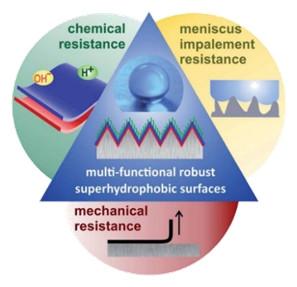

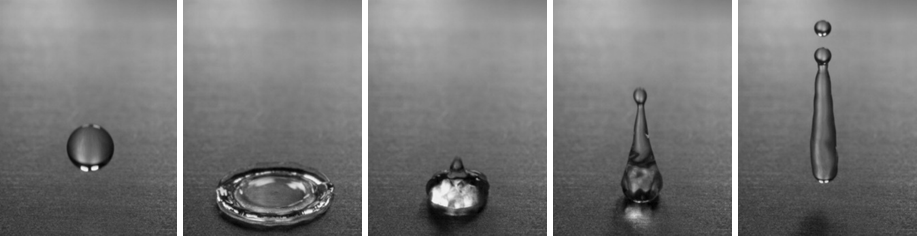

Surface icing can have many negative consequences in a broad range of fields. To avoid sever issues related to ice formation, superhydrophobic surfaces are known to be extremely efficient in terms of reducing ice nucleation and accretion on solid substrates. At SEFI Lab, we rationally design and fabricate advanced materials and surfaces, with hierarchical structuring down to the micro- and nanoscale, providing novel strategies to control phase change processes and limiting negative effects of uncontrolled icing or frosting, and developing new technological approaches for analyzing icing phenomena.

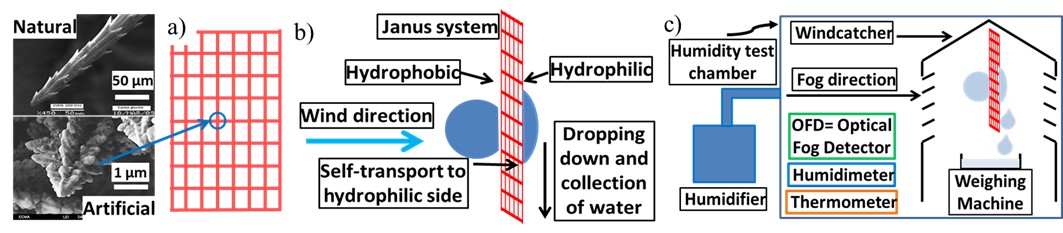

Atmospheric water harvesting

Among all water resources, fog harvesting from atmosphere is highly recommended, because it is a passive method with a considerably lower pollution and does not require high technology and costly operation and maintenance. At SEFI Lab, we are working on a new project on atmospheric water harvesting, named WaterHaB, spanning from studying the fundamental interaction of water with fibers and meshes, to engineering a windcatcher tower, modelled after a Badgir, an ancient Iranian architecture on building rooftops for enhancing fog collection.

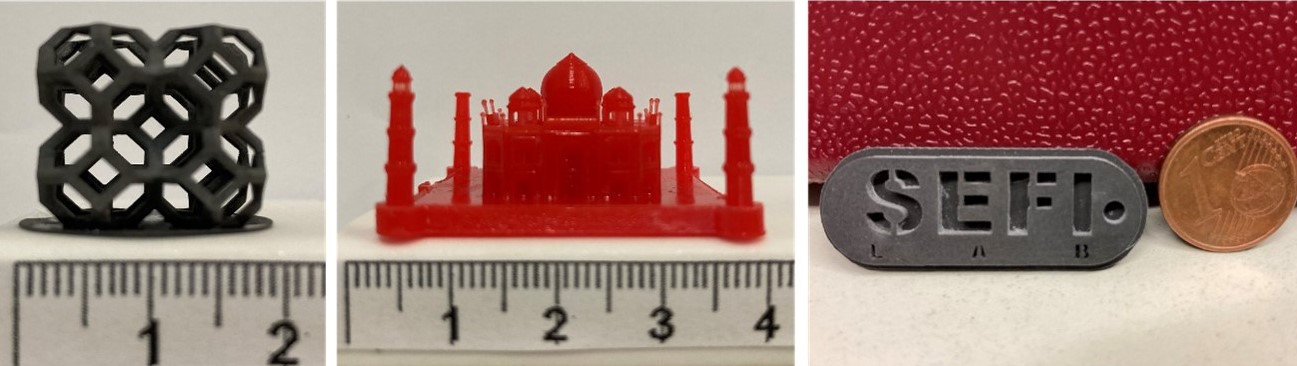

Additive manufacturing (3D printing)

Among all other manufacturing technologies, we are investigating vat polymerization based Digital Light Processing (DLP) technique using liquid photopolymers (resin) as raw material. Also, we are incorporating metallic powder, few microns in diameter, to test the potential of metal printing from metal-loaded resin suspensions.

Functional polysaccharide coatings

Polysaccharides can be used as coatings to control and reduce interaction between proteins and the capillary walls in capillary electrophoresis, with the goal of improving electrophoretic separation. We engineer polysaccharides using different chemical reactions and use them as capillary coatings.

Research group

Prof. Carlo Antonini

Dr. Irene Tagliaro

Facilities

SEFI Lab is equipped for preparation and characterization of coatings and surfaces, with a specific focus on wetting properties. The main instrumentations include:

- a contact angle goniometer for static, advancing and receding contact angles, and contact angle hysteresis.

- a high-speed camera (Photron NOVA S6) per lo studio di impatto di gocce

- a set-up to study ice adhesion on flat samples.