Anion exchange membrane (AEM) technologies are emerging as a key solution for advancing the hydrogen economy by utilizing non-precious materials and reducing environmental impact. Unlike proton exchange membrane (PEM) systems, which rely on scarce platinum group metals (PGMs) and PFAS-based membranes, alkaline systems enable the use of sustainable, PFAS-free materials, thereby offering resilient supply chains and significantly lowering capital expenditures (CAPEX) in hydrogen technologies. However, the adoption of AEM electrolyzers and fuel cells faces challenges, particularly in improving performance to match that of PEMs.

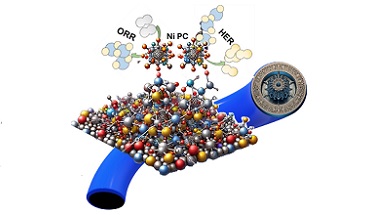

Despite significant progress, including membrane commercialization, optimizing materials for hydrogen evolution reactions (HER) in electrolyzers and for oxygen reduction reactions (ORR) in fuel cells presents promising research opportunities. Nickel, while in the same group as platinum, exhibits lower electrocatalytic activity in acidic media but shows promising performance in alkaline media, particularly in HER. Research has focused on enhancing HER activity by embedding nickel in porous carbon materials or using single-atom Ni on nanoporous graphitic carbon, which significantly reduces overpotentials. Nanostructured nickel composites further improve performance.

For ORR, nickel-based, platinum group metal-free electrocatalysts, especially single-atom electrocatalysts, show promise. However, nickel nanoparticles, which enhance HER, can be detrimental to ORR by producing undesired peroxide. Post-treatment techniques are used to mitigate these issues and improve catalyst stability. One effective method for fabricating such electrocatalysts is using pyrolysis of transition metal (TM)-Nx mixed with carbon. Pyrolysis is a thermal process conducted in a controlled atmosphere to produce durable electrocatalysts by integrating TM-Nx into carbon with atomic-level precision. Factors such as temperature, gas environment, and reaction time affect particle size, porosity, and dopant content. Despite its widespread use, pyrolysis remains not fully understood necessitating further investigation to enhance electrocatalyst performance.

The research team of the Department of Materials Science of the University of Milano-Bicocca (Mr. Seyed Ariana Mirshokraee, Dr. Mohsin Muhyuddin, Dr. Jacopo Orsilli, Dr. Nicolò Pianta) led by prof. Carlo Santoro, in collaboration with Prof. Plamen Atanassov, Mr. Alessio Cosenza at the University of California, Irvine, USA, Dr. Enrico Berretti, Dr. Laura Capozzoli and Dr. Alessandro Lavacchi at CNR-ICCOM, Florence, Italy, Dr. Rosanna Viscardi at ENEA and Dr. Francesco D’Acapito at CNR-IOM (beamline BM08 ESRF) Grenoble, France, initiated a comprehensive investigation that was undertaken into the pyrolysis of Nickel (II) phthalocyanine (NiPc) mixed with Ketjenblack EC-600JD (KJB) across temperatures from room temperature to 1000°C in an Ar/H2 atmosphere to explore the evolution of nickel sites and the support structure.

A combination of ex-situ and in-situ techniques was employed, including X-ray absorption spectroscopy (XAS) to monitor nickel's chemical environment, and various microscopic and spectroscopic analyses (TEM, Raman, XPS, XRD) to assess structural and morphological changes. This approach allowed a detailed description of material evolution during pyrolysis to be provided. It was revealed that the temperature-dependent developments of active site structures significantly affected electrocatalytic performance. HER was improved at higher pyrolytic temperatures by reducing overpotentials, while ORR was negatively impacted by a decrease in the half-wave potential and limiting current.

Nanoparticle formation was detected above 600°C, with particle size increasing with temperature, as shown by XRD, HRTEM, and XAS data. Oxygen complexes were not formed with nickel, as demonstrated by the consistency between in-situ and ex-situ XAS spectra. Enhanced HER activity was observed with the presence of Ni nanoparticles, while ORR performance was more related to secondary active sites, such as N-pyridinic nitrogen, which contributed to reduced peroxide production. Valuable insights into the structure-property relationships of Ni-Nx-C electrocatalysts were provided by this integrated analysis, highlighting critical factors influencing their performance.

The results of the research are reported in the paper “Ni-Phthalocyanine Derived Electrocatalysts for Oxygen Reduction Reaction and Hydrogen Evolution Reaction: Active Sites Formation and Electrocatalytic Activity” (DOI: 10.1021/acscatal.4c03814) published in ACS Catalysis (Impact Factor 11.3, Journal Citation Report (Clarivate Analytics, 2023)).