The storage of gases such as H2 and CH4 and the capture of CO2 are closely related to the use of clean energy, environmental protection, and industrial production to ensure sustainable development of our planet. In particular, the storage of H2 and CH4 are essential for the use of clean energy while the separation and purification of CO2 is essential to reduce the greenhouse effect. In recent decades, extensive progress has been made in the field of synthesis of ultramicro- and micro-porous materials with particular emphasis on the chemical-physical properties desired to achieve the required performance in the field of storage and separation.

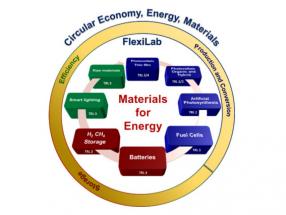

One of the five research topics addressed by the FLEXILAB Project, "Departments of Excellence" project 2018-2022 concerns precisely the storage of gases for the use of clean energy and the purification of CO2 to reduce the greenhouse effect.

We interview Prof. Angiolina Comotti, professor of Industrial Chemistry of the Department of Materials Science and work package leader of this research activity, to understand the potential of the nanoporous materials and the results achieved during the project.

What is the goal of the project?

The project involves the design, synthesis and structural characterization of innovative nanoporous materials that provide high adsorption capacity and ensure high selectivity and specificity for the selected gases. The guidelines for building porous architectures are based on the principles of self-assembly and self-organization with channel and cavity geometries suited to the size of the gases of interest.

What are the advantages of this type of porous materials compared to traditional ones such as zeolites and activated carbon?

Compared to traditional porous materials, these new material classes such as metal-organic frameworks (MOFs), porous organic 3D polymers (POPs) and crystalline molecular materials (PCMs) offer a high surface area, a tunable structure, and a wide range of functionalities, which makes them promising for applications in this field.

What are the results achieved with the project?

New ultra-microporous materials have been developed with high mobility and flexibility that contain nano-sized cavities and rearrange in the presence of gases, increasing the amount of gas captured. In particular Metal-Organic Frameworks have been synthesized based on inorganic clusters of Zn and Zr, the latter are particularly stable in the air and stable up to temperatures of 300 ° C, therefore suitable in environmental operating conditions. New MOFs based on Fe ions and containing fluorinated ligands made it possible to generate C-F dipoles without excessively reducing the space available to gases in the pores. These C-F bonds allow to highlight the role of fluorine-hydrogen interactions and to increase the capture efficiency of gases such as CO2 and CH4. The role played by the pore size in improving the gas-matrix interaction energies was also investigated, and it was found out that 4-5 Å pores are ideal for H2 and CO2.

The absorption capacity of the materials and flexibility have been studied by the use of gas absorbers that operate at different temperatures from 77 K up to 350 K and pressures up to 20 bar. The gas-matrix interaction energy that represents the fundamental parameter for evaluating the performance of porous materials in gas capture was measured in situ using the microcalorimeter coupled to the absorption isotherm apparatus. Relevant values of CO2-matrix interaction of 35 kJ / mole were measured, this value allows both a high capture and release efficiency in environmental conditions and guarantees an excellent "working capacity".

Porous covalent polymers, made up of tetrahedral units, were used to create “switchable” materials. Molecular switches included in the framework made it possible to modulate the amount of gas absorbed on command by the irradiation with UV-visible light. This strategy is particularly innovative because it allows both the storage and the release of gas to be controlled by means of an external stimulus, optimizing the delivery cycle.