3D Printing by photopolymerization is one of the simplest strategies to print and build polymeric materials. Nonetheless, printing process reproducibility requires that photosensitive resins are correctly characterized via the so-called working curve, that provides information on the energy necessary to induce photopolymerization. It sounds easy, but data in the literature and lab experience suggest a significant data scattering, limiting 3D printing reproducibility.

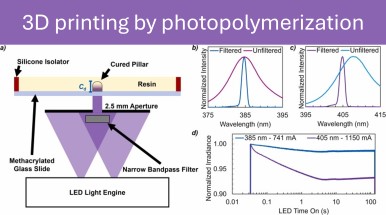

In this comprehensive research article "Results of an interlaboratory study on the working curve in vat photopolymerization II: Towards a standardized method" (DOI: 10.1016/j.addma.2025.104919) published on Additive Manufacturing (Elsevier, Impact Factor 11.1), the authors developed and tested calibrated, narrow bandpass filtered light sources for working curve measurements. Using these standardized light engines, the variability between laboratories was dramatically reduced compared to the initial study, achieving reliable measurements with relative uncertainties of 9.4% (with light wavelength of 385 nm) and 5.5% (405 nm) for depth of light penetration, establishing foundation for documentary standard in photopolymer additive manufacturing. Based on this interlaboratory study, photopolymer additive manufacturing industry can share reproducible and interoperable working curve data.

This research article has been successfully carried out through a collaboration between a team of researchers of the Department of Materials Science at University of Milano-Bicocca (prof. Carlo Antonini, Rajat Chaudhary and Gabriele Muraca, SEFI Lab) together with the National Institute of Standards and Technology (NIST), USA, which led an international consortium of 27 institutions.